You can use several materials to make small buildings. Brick or stone provide the most substantial structures. You can make them completely of metal, or they might have wooden frames and metal covering. Several plastic materials are suitable for cladding and roofing over wood or metal supports. You can use many manufactured boards with a wooden base in parts of a building. However, most small buildings are made of wood throughout, or with only small amounts of other materials.

This guide is for the woodworker who wants to make one or more small buildings and prefers to use the material he knows. Most of the work is quite straightforward and does not have the complications associated with making good furniture or similar, better-quality woodworking. Obviously, skill is worth having, but you can do much of the work successfully with a little skill and by working carefully. The tools you need are not many. If you have a comprehensive tool kit, you will find uses for it, but it's possible to make many buildings with very few tools, particularly if you get all the wood saved and planed to size from a lumberyard.

You can use hand or power tools. It would not be very laborious to make many small buildings entirely with the aid of hand tools. The advantage of power is mainly in speeding up some operations. You might gain accuracy with some power tools, particularly when you prepare parts in the workshop. On the site, you are more likely to reach for a handsaw or plane, and you will make much use of a hammer, for which there is no satisfactory power alternative. The most useful power tool is an electric drill. A router with a few plain cutters will speed up the making of joints, if you have a portable power saw, you will use it, but you can cut most wood for your building easily with a handsaw.

MATERIALS

You can use almost any wood for a small building. Much will depend on what is available in your area. Some woods are more durable than others, but preservatives on the less-durable woods will give them a long life. In general, there is no need to use hardwood. Most hardwoods are harder to work with than softwoods, and they are unnecessarily heavy. Most are considerably more expensive than softwoods. Some very resinous woods have a good resistance to rot and you can use a few without treatment on the outside. Consequently, they weather to a pleasant color that might blend into the surroundings. You should paint or treat most small, wooden buildings, however, so they are protected from the effects of sun and rain.

You can use any of the common softwoods. Some you will be offered might have a larger number of knots. A few small knots might be acceptable, but for the structural parts, try to get wood with reasonably straight grain and few knots. If a knot is black around its outside, it's loose and will not contribute to strength, even if it does not fall out. A knot without a black rim is less trouble. A knot falling out of cladding or siding would be a nuisance.

For many parts of most small buildings, you can use sawed wood, but where it will show, it's better to use planed wood. Planning at a mill will reduce sizes by about ¼-inch, and you must allow for that. For instance, 2- x -4-inch wood planed all around actually will be about 1¾ x 3¾ inches. If the structure will be hidden between the outside covering and an inner lining, you could use sawed wood and get the benefit of extra strength from the thicker wood. It also should be cheaper. Let your supplier see the material’s list. If he can provide short pieces, you might get a better price and service than if you tried to buy long lengths to cut yourself.

Plywood

You can use plywood in many thicknesses for several parts of a small building. Sheets are mostly 4 x 8 feet, so it's wise to scheme building parts to use sheets whole or to cut economically. Any wood which can have the log rotated and peeled into thin veneers can be made into plywood. Much of the available plywood is made of Douglas fir, which is satisfactory for buildings. You can use many other woods also, some of which have a better appearance and take paint or other finish better.

Many grades of plywood are available. Plywood grades are determined mostly by appearance. Prices can vary considerably and there is no point in paying for plywood free from knots in both surface veneers if one side will be hidden.

More important is the purpose for which you intend to use the plywood. Today, most glues used in plywood have a good resistance to moisture, but this is not always true. General-purpose plywood might only be suitable for indoor use. However, the inside of a small building might also get wet, so it's better to avoid this plywood. External plywood has a waterproof glue. Marine-grade plywood is even better quality than external plywood, as the plies and their choice and arrangement, as well as the glue, suit boatbuilding. There is no need to pay the extra price for the marine plywood. For small buildings, exterior plywood is what you need.

Particleboard

As its name implies, particleboard is made of particles or chips of wood embedded in a resin. Boards are the same size as plywood. For our purpose, it should not be less than ¾ inch thick, for strength and stiffness. You can saw it and plane it, but it's unsuitable for cutting joints.

Most particleboard will suffer if exposed to moisture, so it's unsuitable for outside use, even when you paint it.

Particleboard will make good floors. With its large, overall coverage, it might be better in your building than a floor made of many comparatively narrow boards. Similarly, it makes good one-piece shelves, but would not be suitable in a greenhouse or other place where it would be wet for long periods.

You can nail or screw particleboard. For nails near an edge, it's advisable to drill undersized holes, to avoid breaking out. For screwing into particleboard, a tapping-size hole should be taken as far as the thread will go. A screw will not cut its own way to the full depth, as it will in wood.

Hardboard

Hardboard is made from compressed wood fibers and the sheets commonly available have one very smooth side and a patterned, opposite side. Sheets are the same size as plywood, but the thickness is only 1/8-inch.

The quality of hardboard available varies tremendously, and is largely dependent on its density. Some of it's little better than cardboard and will disintegrate in a similar way if you allow it to become wet. This hardboard, and even the better-quality, general-purpose hardboard, is unsuitable for use in a small building, except possibly for backs of cupboards or bottoms of drawers in the furnishings of the building. You could use it as a lining, when there is insulation material between it and the outer covering, but the oil-tempered type would be better.

Hardboard might be treated so it has an oil impregnation. This oil gives it a resistance to water. It is not waterproof if subjected to moisture for a long period. Trade names vary, but there is something in the name to indicate “oil tempered” or a similar term. You can use oil-tempered hardboard for the outside surface of a building, but you must paint it constantly. Better coverings are available.

You can obtain hardboard sheets already perforated with a pattern of small holes. It might be called “peg-board” or something similar. The material is not usually oil-tempered. Many metal clips are available to hook into the holes. These clips will make tool racks. Peg board also will make a ventilated lining, but hardboard has only limited use in a better small building.

Insulation

For many purposes, it might not be necessary to consider insulation for a small building, if it's just a store for garden tools, the inside temperature might not be important. If it's a workshop for year-round use, you will want to keep a comfortable temperature whatever the condition is outside.

Wood in itself provides some insulation, better than metal or solid plastic. If you have wood outside and wood or hardboard lining, the air between also will provide a temperature barrier. You will improve this temperature barrier by adding one of the insulation materials used in home buildings, such as fiberglass. Wall insulation will be helpful, but roof insulation is important and not so easy to provide. Heat rises and much could escape through an uninsulated roof. A lining could hold insulation material directly under the roof, or you might fit a ceiling with insulation material above it. A wooden floor, providing the wind can't blow under it, might be its own sufficient insulation.

Precautions to keep heat in also will work in reverse, if keeping cool is your problem. You can then have plenty of open windows and doors to increase ventilation. Whether heat or cold is your problem, ventilation is important, otherwise your building could suffer from condensation. Arrange ventilators low and high, so air can circulate. You can create a pattern of holes with flaps to cover, if the breeze is in the wrong direction, or you want to keep out rodents.

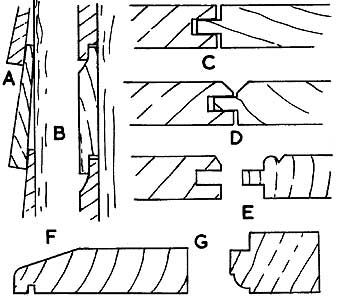

figr. 2-1. Arrange or join boards in several ways to provide

weather-proofness (A,B,C, D,E) A groove under a sill stops water from running

underneath. (F). You can mold a section with a rabbet (C).

Wooden Sections

Most of the wood you use in a small building will be plain, rectangular sections and in stock sizes. For covering, boards are made that provide weatherproofing, even if they expand and contract. If the boards are to shed water, arrange them horizontally so they overlap. One type has a tapered section (figr. 2-1A). A better type fits flat and is cut to provide the overlap (figr. 2-1B). This procedure might be called shiplap, from the way you lay planks of lapstrake boat skins.

If you are to lay the boards vertically, they might have tongue-and-groove joints. The plain joint is not as attractive as some others. If the wood shrinks, the gaps are very obvious (figr. 2-1C). You can make this gap less obvious with chamfers (figr. 2-1D). Another form which disguises the gap has a bead (figr. 2-1E). Doors are usually made with vertical boards, even if the wall cladding is horizontal.

The window surround must protect wall-covering boards. In particular, rain must not run behind the boards. At the bottom, there should be a sill with its top sloping to shed water and a groove underneath to prevent water from running back (figr. 2-1F). Stock sections are available.

Window glass is fitted best into a rabbet. If you do not prepare your own, you can buy a stock section. This section might be molded also (figr. 2-1G). A rather similar section might be available for a door surround and another for a door step. Unfortunately, some stock sections are meant for home building and might be too big for a small, wooden building. Check what is available locally and you might be able to plan details of your building to use these standard pieces.