You can nail many parts of a small building. There might be no need to do anything more elaborate than put one piece of wood on top of another and nail it there. Occasionally, screws might be more suitable than nails. Usually there is no need for glue as well as nails, but a waterproof glue will strengthen the joint. Anything less than a fully-waterproof glue would have only a brief life.

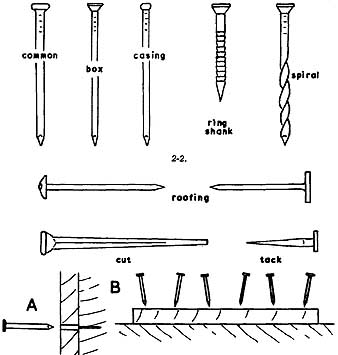

For most assemblies, you can use common or box nails. If you want the heads to be less prominent or wish to punch them below the surface, casing or flooring nails with small heads are available. Their grip is not as strong so you need more of them. For increased hold in the lower piece of wood, ring-shank or barbed-ring nails are available. Another increased-hold nail has a twisted shank. For corrugated roofing, nails with special heads and other roofing nails made with large heads (figr. 2-2) are available.

Driving a nail has a splitting action on the wood fibers. In most positions, this splitting is not enough to matter, but near an end or when using very large nails, it's advisable to drill before driving. You should drill deep enough to clear, or almost clear, the top piece, and you need to drill an undersized hole in the lower piece (figr. 2-3A). An increased grip comes from driving nails at alternate slight angles (figr. 2-3B) to give a dovetail effect. This technique of driving nails with increased grip should be used only when you are certain the joint will never have to be pulled apart. Levering the joint open then might break out fibers or split the wood.

figr. 2-2. (above) You use a variety of nails in constructing small

wooden buildings. figr. 2-3. (below) Drill for nails

to avoid splitting (A). Dovetail nailing (B) is stronger than straight

nailing.

Nails commonly are made of steel and they probably will be your choice for general construction of a building, but steel will rust. It might not rust enough to matter, but nails in very wet conditions can rust away completely. Rust also might come through the paint and leave brown spots or streaks. You can purchase steel nails that are protected by galvanizing (coating with zinc) or other corrosion-resistant metals. Stainless-steel nails are expensive. Aluminum nails will not corrode enough to matter. If you are nailing through metal, it's better to use nails of the same metal, to prevent electrolytic action between different metals, causing corrosion. This corrosion might happen with aluminum guttering.