|

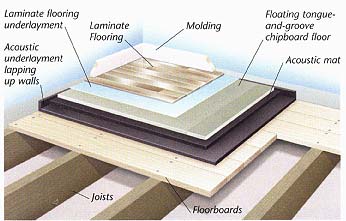

Noise pollution comes in two forms—airborne and impact—and soundproofing products are often classified by the type of noise they affect. Airborne sound can be created by televisions, stereos, or speech. Impact noise travels as vibrations through solid materials, and includes footsteps or furniture being moved. Soundproofing a floor is easier than soundproofing a ceiling, but if you live in an apartment you may not have a choice. Most soundproofing efforts are done to block-out sound, whereas in many renovations and newer houses, great effort is taken to soundproof theatre rooms to create an enhanced “theatre-like” experience. Soundproofing a FloorCombining acoustic underlayment with acoustic mats beneath a floor

reduces the effects of both airborne and impact noise. If the problem

is solely impact noise, underlayment alone may suffice. Remove

the coverings to reveal the floor (see Flooring).

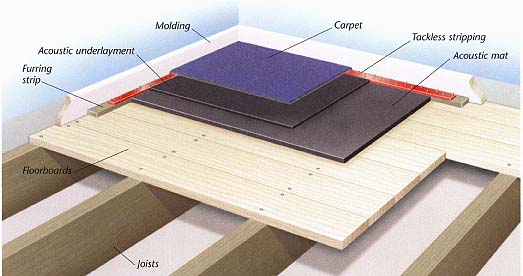

If the floor is to be carpeted, leave the baseboard in place and

proceed as shown below. For other floorings (see image), remove

the baseboard molding and lay out the acoustic underlayment, butting

the lengths up against one another and allowing them to lap a short

distance up the wall. Tape all joints, and then lay acoustic mat,

ensuring that any seams do not coincide with the joins of the underlayment.

Lay a floating tongue-and-groove chipboard floor over the top,

and trim the edges of the underlayment. You may then install further

floor coverings, such as laminated

flooring. |

Soundproofing hard floors: A combination of acoustic underlayment with acoustic mats and chipboard sheets is a very straightforward option for effective soundproofing. Here it is installed below a floating chipboard floor, over which underlayment and laminate flooring are laid. |

Soundproofing carpeted floors: When soundproofing floors that are to be carpeted, first install furring strips around the room’s perimeter, then lay acoustic mats and underlayment between, and butting up against, the furring strips. Attach tackless stripping to the furring strips and lay the carpet. |

Flooring materials and soundproofing

As soundproofing involves the building up of materials, thick floor coverings are more soundproof. For example, cushioned vinyl is more effective than regular vinyl. You can lay sheet vinyl over a soundproofed chipboard floor and attach it with double-sided adhesive tape. Similarly, high-quality burlap-backed carpets will prevent sound travel better than cheaper foam-backed carpets.

Do not add flanking strips to a carpeted floor. The fact that the carpet stretches across the tackless stripping and makes contact with the baseboard should provide protection enough against flanking noise.

Doors and Windows

- Double glazing windows or glass doors improves sound insulation, as well as thermal insulation.

- If noise from outside is a major problem, consider triple glazing.

- Weatherstripping added around doors and windows will insulate them against sound as well as heat loss.

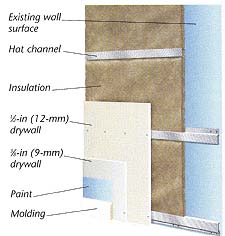

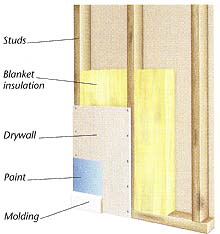

Reducing Sound Travel

- Sound is created by vibrating material. Making a room stiff and thick reduces the amount of sound that can escape.

- Using acoustically efficient materials to add mass to a structure increases its ability to absorb sound.

- Structural elements carry sound, so creating a barrier between them prevents sounds from traveling across a room.

- Use acoustic sealant, flanking tape, or flanking strips to isolate a structural element.

- Seal the edges of walls and floors to prevent sound from traveling to the next room.

Next: Ventilating a Home