|

A relatively recent development in the history of cloth, knitting has grown through technical advancements from a tedious hand construction to a fast, economical means of producing comfortable, packable, and beautiful fabrics. Knits owe their many advantages to their structure. While the yarn in a woven fabric is in a straight position, the knit construction arranges a continuous yarn into interlocking loops. Since these loops can straighten out under tension without straining the yarn, knit fabrics are inherently stretchy and flexible. Several terms are used to describe knit goods. The gauge of a knit refers to the number of needles in 1" to 2" (25 mm to 5 cm) of fabric, depending on the type of knit. Denier is a term dating from Roman times, when the weight of a coin by that name was used as a standard for buying and selling silk. It describes the weight of the yarn per unit length. A wale or rib is a column of loops running parallel to the long measurement of a knit fabric, corresponding to the lengthwise grain of a weave, and a course is a crosswise row.

|

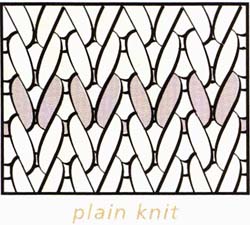

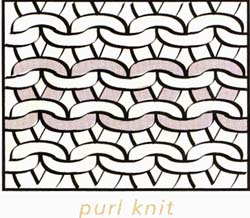

Weft KnittingThe first knitting machines were designed to reproduce the type of knitting done by hand. Called weft or filling knit, this construction uses a continuous single thread to form a crosswise row of loops which links into the previous row and is in turn linked into the row that follows it. Two stitches, knit and purl are the basis for all knitting constructions. The knit stitch is a loop drawn through the front of the previous one; the purl is drawn through the back. Simple weft knits are uniquely fragile, since all the loops in a vertical row are dependent on each other. A broken loop will release all the others in the row, marring the fabric with a run. Wool knits tend to have greater resistance to runs because of the capacity of the wool fibers to cling together, locking the stitches. Weft knitting produces fabric in both tubular and flat form. PLAIN KNITS, found in the familiar fabric known as jersey, have a flat surface and a back characterized by short, horizontal loops. The right side exhibits the appearance of the knit stitch, and the loops on the back are the purl stitch. This structure is a common feature of hand knitting, where it is called stockinet. PURL KNITS also have pronounced ridges, but in a horizontal direction. Entire rows are formed alternately of knit and purl stitches, yielding a fabric that has considerable crosswise stretch. It is completely reversible, since the appearance of the face is identical to that of the back, and similar to the reverse side of the jersey knit. |

|

- Google listing

of all "Fabric" items on our site

- Yahoo! listing

of all "Fabric" items on our site

- Alta Vista listing of all "Fabric" items on our site

Recommended Reading

Recommended Products

Want to learn more about sewing, knitting and related arts and crafts? Browse our reading list.

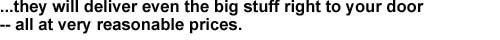

RIB KNITS are made by alternating sets of knit and purl stitches in the same row, forming pronounced vertical ridges. The purl stitch tends to recede while the knit stitch advances, creating a fabric with a wavy cross-section and superior crosswise stretch. Rib knits have good insulation properties, and provide a snug fit. These knits are referred to by the number of knit and purl stitches used to make the pattern, thus 1 x 1 rib or 2 x 2 rib and so on.

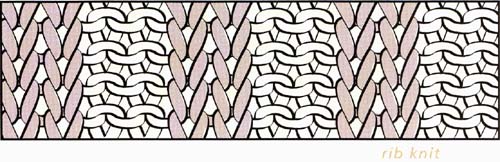

PATTERN KNITS are produced from the two basic weft knit stitches by rearranging, dropping, adding, alternating and crossing them. For example, the beautiful “fisherman knits” are prime examples of the vast variety of patterns that owe their depth of texture to the fact that the knit stitch tends to advance and the purl stitch to recede. The machines that produce these fabrics, while not economical to operate, can recreate hand-knitted looks in standard fabric widths and lengths.

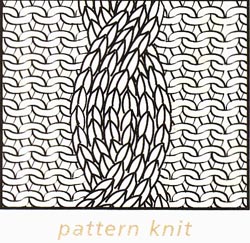

DOUBLE KNITS are a versatile form of weft knitting that resists runs and have good stability. These fabrics use the interlock stitch, a variation of the rib stitch that can only be done by machine. Double knitting uses two yarns and two sets of needles that draw loops through from both directions. It is a heavy, firm, easily handled fabric that can have the same rib like appearance on both sides. Jacquard-type machinery has been adapted to produce highly decorative double-knits.

Warp knittingWarp knitting, unlike the simpler weft knitting, employs many yarns. Wound parallel to each other on a warp beam, the yarns are fed into the knitting machine and form loops in the lengthwise directions. Each yarn is controlled by its own needle and follows a zigzag pattern, interlocking with its neighbors along the length of the fabric. Warp knitting produces several kinds of durable and relatively run-proof fabrics whose low cost and vast design potential have won them enthusiastic consumer acceptance and a secure place in the textile industry. |

|

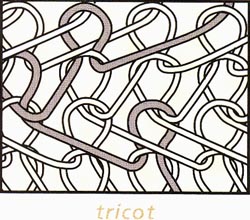

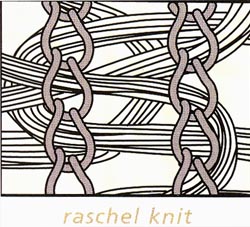

| TRICOT is used extensively for lingerie because of its good permeability and comfort. Available in a wide variety of weights, it is suitable for dresses, loungewear and linings. This is a strong and drapable fabric that can be recognized by the fine crosswise rib that appears on the wrong side. It stretches much more in the crosswise direction than in length. It is resistant to running and fraying. RASCHEL KNITS can be produced in a wide variety of yarns. While tricots and many weft knits are best suited for fine, uniform yarns, Raschel knits can take advantage of every conceivable texture and fiber type because of a specially designed latch needle. Raschel knits range from fragile tulles to coarse fur cloths. A chain of fine yarn, which restrains and stabilizes a heavier textured yarn in a lacy, open construction, may often identify them. |

|