The secret of successful sewing begins with selecting suitable fabric for your pattern and for you. The back of the pattern envelope has fabric suggestions. Unless you have a basic knowledge of fabrics it's difficult to choose wisely. The fabric which you have in mind may not be listed among the suggestions, but it may be comparable to one of them and would he suitable for the pattern.

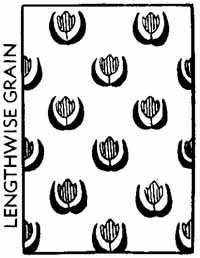

The secret of constructing a garment which will fit perfectly, hang well and keep its shape lies in preparing and cutting the garment with grainline perfection. The fabric is “grain perfect” when the crosswise and lengthwise threads sit at right angles to each other.

It isn't difficult to fit a garment if you use the grainline as a guide. Because the fit depends on the grainline, all pattern Pieces must be cut on the correct grainline. A garment cut on the grainline will hang gracefully and hold its shape.

The grainline perfection of the fabric is established when you prepare the fabric for cutting by straightening and , if necessary, by stretching so the fabric will “lie square” (crosswise and lengthwise grainlines at right angles).

FABRIC CONSTRUCTION

Fabrics are constructed from yarns made from natural or synthetic fibers. The yarns are woven or knitted into fabrics.

Woven Fabrics

These are constructed with two sets of yarns that run at right angles to each other. The lengthwise yarns (warp) run the lengthwise of the fabric, are the stronger threads, and are known as the lengthwise grain. The se/cage (selvedge) is the specially woven edge on each side of the fabric that prevents it from raveling. The crosswise (weft or filling) yarns run from selvage to selvage and are known as the crosswise grain. The three basic weaves are plain, twill, and satin.

Plain weave — simplest and commonest of the basic weaves; produces durable fabric. In solid color, has no right or wrong side, unless loose thread ends are visible. Easiest to use; recommended for beginners.

Twill weave — either warp or filling yarns are interlaced with the others in a staggered manner forming a diagonal ridge or twill; produces very durable fabric. Does have right and wrong side. On some, such as drill and gabardine, diagonal ridge is very pronounced, limiting choice of pattern style because careful cutting is required. If pattern isn't suitable for obvious diagonal fabrics, it's indicated on both pattern book and envelope. Be sure to check before buying your pattern, if you have an obvious diagonal fabric in mind.

Satin weave — similar in construction to twill, but the twill is broken by floating the yarn over a number of threads, producing a more lustrous fabric but a less durable one. Float threads tend to catch, snag and scar if scratched. Fabrics with a satin weave have an up and down, and call for directional (one way) cutting. They often require more material, as indicated on the pattern envelope. Should be avoided by beginners.

FIGURED WEAVES

These are constructed on looms with special attachments that produce woven-in designs.

Dobby — small, simple designs such as dots, squares, diamonds, etc. (dobby taffeta, huckaback towelling, birdseye, waffle cloth)

Jacquard — large, elaborate designs. (tapestry, damask, brocade) Matelasse the design has a quilted or cushioned effect.

Seersucker fabric — has a crinkled stripe made by weaving some of the warp threads slack and others tight. Woven seersucker is more expensive than chemically achieved imitations.

Pile fabric — has cut or uncut loops which stand up densely on the surface. The closer the weave the more durable the pile. Velvet, velveteen, corduroy are examples of cut pile or loops. Turkish toweling, terry cloth, carpets are examples of uncut loops.

Napped or brushed fabrics — finished by brushing the fabric to bring out fiber ends from soft, loosely-twisted filling yams. Napped fabrics may be woven with a plain or a twill weave, or may have a knitted construction. Nap sometimes conceals a sleazy construction. Over-brushing weakens the fabric.

Flocked fabric — “Flock” dots or designs are sometimes applied to fabrics to give a velvety look to the design. Paste is applied to the area to be flocked and the fabric is dusted with short fibers.

KNIT FABRICS

Knitting is a process of constructing fabric by interlocking a series of loops of one or more yarns.

Weft or filling knits — usually tubular, having right and wrong side like hosiery. The vertical rib represents the lengthwise grain. Crosswise grain will be at a ninety degree angle from lengthwise grain.

Warp knits — different type of interlocking, flat. Have less stretch, are firmer and stronger than weft or filling knits. Do not run or snag. Tricot is a warp knit.

Double knits — formed by two sets of yarns and needles, each knitting a single fabric and interlocked at regular intervals; more body and weight than single knits.

The chain stitches running lengthwise of the fabric are called “wales” and represent the lengthwise grainline. The crosswise ridge can be observed from the wrong side of the fabric and represents the crosswise grainline. After straightening they can be made to “lie square” by stretching on a true bias.

Some synthetic knits have become locked in an off-grain position during finishing processes and are impossible to straighten. Avoid buying such fabrics if they are much off grain. Many wool and cotton knits termed “washable” have been permanently treated for shrinkage and can't be straightened.

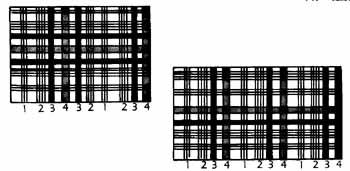

PLAIDS and CHECKS

If the plaid or check is woven into the fabric the lines will form the lengthwise and the crosswise grainline of the fabric. If the plaid or check is printed on the fabric the lines may or may not be on the grainline. A thread must be pulled to establish the crosswise grainline. Avoid buying printed plaids and checks unless you inspect them carefully.

STRIPES

If the stripe is woven into the fabric the stripes will be a guide when establishing the grainline. Crosswise woven stripes will represent crosswise grainline. On lengthwise striped fabrics a thread must be pulled to establish crosswise grainline.

Remember: printed plaids., checks and stripes may be printed “off grain” and are not recommended for beginners.

PRINTED DESIGNS

The color is applied after the fabric is woven. In all patterned fabrics, woven as well as printed, there is a place on the fabric where the design or motif is repeated. These repeats are usually at regular intervals. In many designs the repeats must be matched to produce an attractive garment, especially in large designs or motifs (drapery fabric is a good example). Extra fabric will be required for matching. A very small design or a “mixy” indistinct, all-over design doesn't present a problem when laying out your pattern, as it doesn't require matching. The crosswise grainline can be established by tearing or by pulling a thread.

If the design is clear cut or has an isolated motif it may appear to be following a straight line across the cut end of the fabric, but when a crosswise thread is pulled, it has been printed “off grain” and the designs will not he in a straight line. This will not give a pleasing effect on the body and will be very noticeable along the hemlines of the sleeves and skirt, also on the hemlines of drapes. Before buying a printed fabric it's advisable mo observe whether or not the end of the fabric on the bolt has been torn or cut. Check the design in relation to the crosswise grainline.

Bonded, heat set, and permanent press fabrics don't have to be made grain perfect before cutting because the grainline has been locked in by the finishing processes and they can't be straightened.

Consumers are demanding more and more information regarding fiber content, finishes and care of fabrics; also that such information be permanently attached to all textile products that they buy. So, it behooves every consumer to understand this information, particularly when shopping by telephone and catalogue. It is equally important that sales clerks be qualified to supply reliable information.

Remember:

1. If the fabric can be straightened and you don't straighten it, the fit and hang of the garment will be affected; the hang of drapes will be affected.

2. Pleats will hang better, hold the crease and press better, when lengthwise grainline runs lengthwise on the body.

3. Pants cut on lengthwise grain hold their crease and don't get as “baggy” in the seat or knees.

4. Gathers — in skirts, yokes, and sleeves will be more attractive if lengthwise grainline runs lengthwise on the body. The exception to this is when some fabrics have a mixture of natural and certain synthetic or man-made yarns.

If your pattern has gathered sections, make two samples of gathers, one with the three rows of gathering stitching placed on the crosswise grain line (the lengthwise grainline will then be on the lengthwise of the garment); on the other sample, place the three rows of gathering stitching on the lengthwise grainline of the fabric. Pull up gathering threads. The difference in appearance and hulk is very obvious. Usually when gathering stitches are on crosswise grainline the result is more attractive. If running the other way, they have a “hunchy” look and produce a bulky seam when attached to the rest of the garment.

This must be decided before cutting, and as you will not have scraps of fabric you will have to use the fabric — gathering stitching can be removed later. You might be able to determine the appearance by pulling a thread, but be sure before you cut.

Remember: Frills, ruffles and flounces are also gathered sections; are cut and gathered as for a skirt (gathering stitching on the crosswise grainline).

I know of a home dressmaker who was gathering a section of the garment for smocking; the fabric had a mixture of pure silk and of a new man-made yarn. The effect was so very unattractive that she had to cut a new garment piece and run the gathering stitching on the other grainline. Fortunately, she was able to get more fabric.

TERMS USED in DESCRIBING FABRICS

Some textile companies and pattern companies publish inexpensive dictionaries — fabric terms, pattern terms, fashion terms, sewing terms, etc. Many terms have similar meanings and are used interchangeably, such as, drape, “hand”, “feel”. You must learn to understand these terms, to know how a fabric will shape into the style you have chosen.

Drape — how a fabric will fall when hung.

- Hand and Feel — refers to touch, weight, body, drape, of handle of fabric. Some finishes contribute to feel and hand of fabric.

- Texture — surface effect, such as, dull, lustrous, woolly, stiff, soft, fine, coarse, open, closely woven — used in conjunction with drape, hand and feel.

Become a “fabric feeler”. Feel the fabrics in the yard goods departments. 1-lold it in the direction in which it will eventually hang.

Does it fall in graceful folds? Will it gather softly? Will it hold pleats? Will it be firm enough to retain the shape if the garment is close-fitting?

- Sleazy — a trade term used to describe poor quality in a fabric; thin,

lacking firmness, loosely woven.

- Loft — the springiness or resilience of wool and wool-like fibers and fabrics; indicates how it will resume its normal position after it has been stretched or squeezed.

ON-the-SPOT TESTS for QUAUTY and DURABILITY when SHOPPING

1. To determine shape-holding qualities — pull fabric lengthwise and observe amount of stretch; pull fabric crosswise.

2. To determine strength — grasp fabric firmly between thumb and fore finger of both hands, pull gently. Move thumbs back and forth over fingers. Weak fabrics tend to pull apart and wear thin where it has been stretched.

3. To test for wrinkle resistance — crush or twist a corner of fabric. If sharp creases form, like those in paper, it will crease badly and creases will not “hang out”; they will require pressing. If creases have a soft rounded look they will likely “hang out”. A sure test is to tie a knot in a sample or corner of the fabric. Good sales clerks will often do this to demonstrate degree of wrinkle resistance.

4. Test for ability to take pleats — fold pleats in fabric; crease edges of folds with fingers.

5. Check all printed plaids and stripes on crosswise grainline for ac curacy in print. Sometimes it's more obvious on wrong side. A sure test is to pull a crosswise thread.

6. Check float threads on satin weaves ask for a sample; lift float thread with a pin. The longer the float, the less durable the fabric.

7. To determine amount of stretch in knit fabrics — pull fabric lengthwise and crosswise. Some stores have charts to show and compare the degree of stretch in their knit fabrics.

8. To determine durability of pile fabrics — twill back is more durable than a plain back. Hold fabric up to the light to determine closeness of weave.

9. To determine durability of nap — hold fabric up to the light. Lift the fabric off the table by the nap. A durable nap supports the weight of the fabric.

10. To determine piling on napped fabrics — Pilling is the formation of little balls of fiber which occurs on some fabrics when the surface is rubbed. Moisten finger slightly and rub fabric surface in a circular motion. If balls of fluff start to form the fabric is apt to pill.

11. To determine durability of flocking — scrape flocked design with fingernail.

You can increase your knowledge of fiber content, handling, and care of fabrics by saving tags from ready-made garments. New fabrics and finishes are appearing constantly and are written up in magazines, newspapers, and the monthly pattern leaflets. Clip and save them.

How to Distinguish the Right SIDE FROM the WRONG SIDE

The right side of the fabric is often referred to as the face and the wrong side as the back.

- Most fabrics are folded lengthwise when wrapped on the bolt, usually with the right side inside to prevent soiling and fading.

- Cottons are usually folded with right side outside for display purposes.

- Luxury fabrics that crease mark are rolled with right side inside — velvets, pure silk, lace, satin, etc.

- Knit fabrics the right side of many knits resembles right sides of sweaters and hosiery.

- Printed fabrics — design is clearer and sharper in outline on right side.

- Plain fabrics — observe how fabric was folded. Check both sides for knots or for loose ends of threads; these will be on wrong side. Check selvage — right side has smoother appearance.

- Woven stripes and plaids — check for loose threads and knots as with plain fabrics.

- Twill fabrics — Cotton fabrics are usually woven with left-hand twill. Wool and silk fabrics have right-hand twill weave. Whichever the direction of twill on face of fabric, the diagonal ridge runs in the opposite direction on the reverse side. Rule for twill: hold fabric against yourself, lengthwise grainline in vertical position, look down on fabric.

(1) Wool and silk fabrics — twill will run toward right foot on right side of fabric.

(2) Cotton fabrics — twill will run toward left foot on face of fabric. Do not confuse a two-tone diagonal pattern weave, often found in wool fabrics, with a twill. On close observation it's apparent that the raised ridge is absent.

- Reversible fabrics — either side may be used.

- Ribbed or corded fabrics — (bedford cord, pique, bengaline) Rib or cord is more pronounced on right side.

How to DISTINGUISH UP and DOWN

- Pile and short nap take the opposite ends of the fabric and hold them against the body. Look down on them. One end will appear darker and richer in color. Mark this end “top” and place the tops of all pattern pie facing the to of the fabric. There are some velvets on the market with an upright pile and there is no up and down.

- Shaggy, brushed fabrics --made with the shag or brush hanging down because the garment wears better; doesn't rough up as readily.

- Satin — check as for velvet.

Remember: All up and down fabrics can never he cut with a crosswise fold. The fabric must be cut in half and both “top” ends placed together.

If using a lengthwise fold for your pattern layout, place the woven side of pile fabrics together and pile side out because the pile sides would stick together and not lie flat. Pile fabrics should be stitched in direction of pile to avoid slipping and sticking.

- One way designs — Always cut garment pieces so that flowers with stems are in a natural position; trees, buildings and animals should never stand on their hands. All pattern pieces must be placed one way, as for nap or pile.

- Fabrics with a right and left — Some uneven plaids, multicolored, vertical stripes, have a right and left in the design. When laying out pattern plan carefully so that designs will either all face in the same direction or face each other. Designs may require matching at seams.

ALLOWANCE for MATCHING

Styles suitable for plaids, stripes and large hold designs should have a minimum number of seams, because each seam breaks up the design and much of the beauty of the fabric is lost. To determine the allowance for matching, check the layout of pattern pieces, width of fabric and size of design. Determine the number of times the seams will require matching.

- Supposing the size of design or pattern in the fabric is 6 inches, the usual allowance is:

- Simple skirt — 1 extra pattern — 6 inches

- Simple blouse — 1 extra pattern — 6 inches

- Simple jacket — 1 extra pattern — 6 inches Dress or coat — 2 extra patterns — 12 inches