Replacing a heating system with a newer, more efficient system is expensive,

so it will typically have a long payback. However, if you have to replace a

broken furnace or boiler, it is almost always cost-effective to select a high-efficiency

system. Even if your existing heating system is functional but appears to be

on its last legs, replacing it early can help avoid a big surprise at the worst

time. Deciding, rather than being forced, to replace a system significantly

reduces the panic factor and allows for a more reasoned choice. It may even

reduce the cost a hit, because it won’t be an emergency call.

The vent on the left side of this steam radiator has an

adjustment knob at the bottom to control how fast the steam fills the

unit.

Most steam boilers require a periodic addition of water.

This is done by opening a valve on the inlet waterline. Like an oil dipstick

in your car, this sight glass helps you monitor the water level so you

can keep it just right.

SAFETY FIRST

Years ago, materials containing asbestos were commonly used to insulate pipes and ducts. Usually white and fibrous, asbestos is often fragile; if disturbed, it can release dangerous fibers into the air. If your pipes or ducts appear to have asbestos insulation, don’t touch them. The presence of asbestos can be verified by lab tests; confirmed or suspected asbestos materials should either be encapsulated or removed by a qualified asbestos-remediation contractor.

TIP: When shopping for a new furnace or boiler, compare efficiency ratings and get the highest you can afford

WHAT CAN GO WRONG: W hen replacing a heating system, size does matter-- but bigger is definitely not better. A system that is much bigger than necessary is sort of like a big diesel truck engine in a compact car - inefficient, expensive, and hard to control. Any heating-system-replacement bid should include a detailed load calculation based on the thermal characteristics of the house, such as insulation levels, window types, and surface areas. The widespread practice of simply replacing an old unit with a new one of the same size perpetuates the problem. Many homes start out with systems that are much too big; if the thermal envelope has been improved, the oversizing problem becomes even worse.

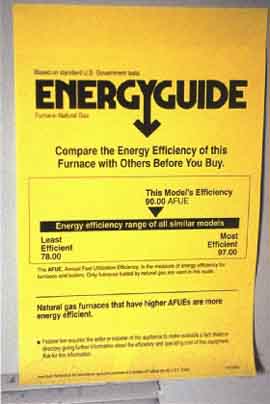

Efficiency ratings

All new boilers and furnaces have standardized efficiency ratings, just like the gas mileage ratings on automobiles. When selecting equipment, look for the highest efficiency ratings. Fuel-fired furnaces and boilers have an Annual Fuel Utilization Efficiency (AFUE) rating, which accounts for burner efficiency, pilot fuel, and off-cycle losses. New furnaces have AFUEs of 78°F to 96°F ; boilers range from about 80°F to 87°F. AFUE ratings are avail able from manufacturers or on the Internet. Air-source heat pumps are rated by HSPF; geothermal, by COP.

The U.S. Environmental Protection Agency (EPA) and Department of Energy (DOE) maintains a listing of high-efficiency equipment on their Energy Star Web Site (www.energystar.gov/products/); always look for the Energy Star label, which indicates that the equipment meets certain above minimum efficiency standards set by the government. Remember that the ratings apply to only the equipment. Installation problems, improper maintenance, and distribution problems (such as duct leakage) can reduce performance dramatically.

If your furnace or boiler looks like this, it may be time

to replace it with a more efficient one, even if it is still running.

The yellow Energy Guide sticker indicates the efficiency

rating of new heating equipment and provides a comparison among similar

models.

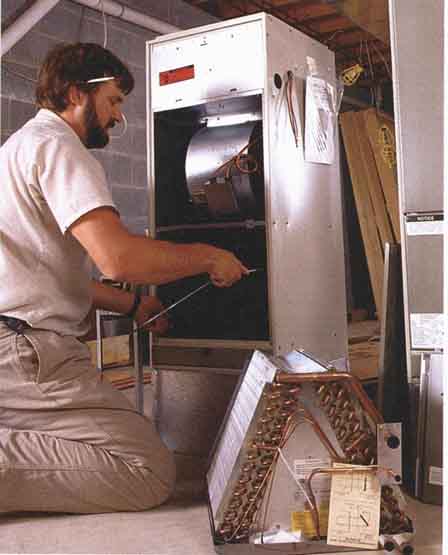

Choosing a contractor

Replacing a heating system is not a do-it-yourself proposition. Because it is a big-ticket item, you should always interview and obtain alternative bids from at least two or three contractors. Don’t be tempted by the lowest bid. Consider quality, warranty service, energy savings, and customer references. Bids should include details on the equipment, accessories, installation specs, labor, and associated costs.

Most high-efficiency furnaces and boilers have special installation requirements to ensure that they work reliably and don’t have problems. Find out whether bidders have experience with the specific type of installation that you are discussing.

Most manufacturers offer training and technical support for newer, more sophisticated equipment, so a contractor who tries to discourage you from installing high-efficiency equipment may be unwilling or unable to read the directions.

Sizing is also important. Many contractors avoid detailed sizing calculations to save time, but the time spent calculating energy loads can easily be paid for by reduced equipment costs. If you talk to a heating contractor who gives you a price over the phone, or without measuring the thermal components of your house, look elsewhere.

When replacing a heating system, it generally doesn’t make sense to switch fuels or replace an existing distribution system with a different type. The most likely exceptions to this rule are the conversion of electric-resistance baseboard heating to a fuel-fired boiler with hydronic distribution and the replacement of an electric furnace with a heat pump or fuel-fired furnace. Except for changes in the distribution system for the purpose of improving comfort or efficiency (such as duct-system changes to increase airflow), there is rarely justification for the large expense of replacing distribution equipment.

Some steam-radiator systems can be retro fitted to use existing radiators for hydronic distribution. The cost will vary considerably depending on the system and the layout of the house. Because hot water boilers are always more efficient than steam boilers, changing a steam system to a hot water system can significantly increase boiler efficiency, improve comfort control from room to room, add the possibility of zoning the house, and reduce noise. Replacing a hot water boiler, or converting from steam to hydronic, is also a good time to replace an inefficient tankless coil or stand-alone water heater with an indirect-fired model.

Hydro-Air Systems

Hydro-air systems are hybrids. They deliver heat to a house by blowing warm air through ductwork, like a furnace does, but the heat source is usually a hot water boiler. Hydro-air systems typically use only one heating appliance to produce heat and hot water for the house, improving efficiency and reducing maintenance. Hot water can be easily piped to several zones with separate air handlers in different parts of the house, without the problems of matching airflow to burner capacity. Hydro-air handlers can also be easily integrated with air-conditioning.

Hydro air handlers use hot water circulating through a heat

exchanger, or fan coil, to heat air pushed through by the blower. The

“A” coil at the bottom is for cooling.

Next: Air-Conditioning (coming soon)