Almost any rigid plastic, from a counter-top laminate to acrylic glass, can

be cut and shaped with the same tools used in woodworking. But the tools are

not always used in quite the same way. The cutting of plastics calls for particular

types of blades, for instance, and there are some additional safety precautions.

When you cut plastics with power tools, make sure the area is well ventilated,

and wear eye goggles and gloves. Protection for your hands is especially important

when you are working with rough-sawed glass-reinforced plastics or fiberglass.

And a respirator is a good defense against particles when you are sawing such

material.

In addition, many plastics are them selves in need of protection while they

are being cut—because they are so vulnerable to scratching and chipping. Be

fore you run a plastic sheet through any power tool, check the work surface

over which the plastic will pass. Even the smallest burr or grain of sand may

scratch the plastic. In fact, if the plastic is sold with a protective paper

wrapping—commonly the case with acrylic glass—it is best to leave the paper

in place while the plastic is being machined.

If the plastic contains no protective wrapping, you can cover it with kraft

pa per or cardboard, held in place with masking tape or water-soluble glue.

To prevent the protective wrapping from clogging the teeth of the saw blade

during cutting, lubricate the blade with beeswax or soap.

In lieu of a wrapping, you can cover the work surface with paper, cardboard

or a piece of felt. When clamping a scratch-prone plastic, always place a wooden

block between the plastic and the jaws of the clamp—whether or not the plastic

has a protective wrapping.

During cutting, most sheet plastic will need support to keep it steady. It

should rest on a fairly large work surface and be pressed down firmly to reduce

vibration. The cut should fall slightly to the waste side of the cutting line,

to allow for edge finishing.

Although power tools cut much faster, almost any handsaw will cut plastic.

Howe the type of blade used is important. Laminates and acrylic glass can be

cut with a standard carpenter’s cross cut saw with fine teeth— 10 to 12 per

inch. A hacksaw or a keyhole saw fitted with a hacksaw blade will also cut

acrylic glass and laminates, as well as PVC pipe and plastic tubing. When small

rods are cut by hand, a V block will help to hold them steady; on round stock,

a groove, cut with a three-cornered file on the cutting line, helps to hold

the blade during its first strokes.

Of the smaller power tools, the stationary jig saw and the portable saber

saw are the most versatile. Not only will they cut all types of plastics but

they will handle a range of cuts, such as bevels and curves. Either saw is

especially good for cutting intricate patterns or small-radius circles in plastics

up to ½ inch thick. However, it’s important to fit them with fine-toothed blades

when you are cutting fiberglass or glass-reinforced plastics.

When cutting with a jig saw or a saber saw, stop the saw and back it out as

soon as it starts to bind. Unfortunately, the heat of a power tool’s fast-moving

blade tends to melt the plastic and clog the teeth of the saw. It may even

fuse together the cut plastic edges behind the blade, trapping the blade in

the work.

In general, this problem of clogging and fusing is easier to deal with when

you use larger power tools. With table and circular saws, for instance, a wider

choice of blades allows you to use a hollow-ground blade with small teeth.

Such a blade resists clogging and makes a smooth cut, lessening the tendency

of the cut edges to fuse together. With a band saw, the blade has a chance

to cool before it reenters the cut.

Another advantage of a band saw is that the plastic chips are dislodged from

its blade as it travels around its circuit, resulting in a very smooth cut.

However, the wheels over which the blade travels will occasionally need lobe

cleaned with a wire brush or a file card.

Unfortunately, plastics quickly dull saw blades. For this reason, it may be

wise to keep an assortment of blades exclusively for working with plastics.

Any blade made for cutting plywood is suitable, if it has the necessary number

of teeth per inch, but there are also blades made especially for cutting plastics

and so labeled. The blades that stay sharpest are carbide-tipped ones—available

for band, circular and table saws—but they also are more expensive than regular

blades.

In cutting laminates, especially those not backed with plywood, a major problem

is likely to be chipping and cracking, but there are several ways to minimize

the risk. One is to press transparent tape over the cutting line. Another is

to round interior corners of openings in counter- tops, such as those for a

set-in sink; both during and after cutting, rounded corners are less likely

to split than square ones are. A third way to protect the laminate from damage,

useful when working with a handsaw, is to place the decorative surface face

up and hold the saw at a low angle, moving it in short strokes.

For trimming away excess laminate and shaping a corner at the same time, a

router is useful. It can also cut a V groove in acrylic glass so that the piece,

when heated, can be bent to a right angle, forming a sharp interior corner.

As with power saws, if you often use a router for plastics, it pays to invest

in a carbide-tipped router bit.

Some plastics can be cut without a saw. For example, acrylic glass up to ¼”

thick can be scored and snapped in two—but only when the piece removed is at

least 1½” wide and only when the acrylic is unpatterned, because the bumps

at the pattern will cause an uneven score and break. For this technique, shown

opposite, you will need a steel square and a ¾” dowel, as well as a nail, a

linoleum cutter or a special scoring tool designed for plastics. The plastic

is snapped while the protective masking paper is still in place, and the paper

is cut with a knife or a razor blade.

Small rods and tubing can be cut with out a saw, too. First a notch is filed

at the cutting line, then the piece is held in both hands, notch facing away

from the body, thumbs of both hands together and behind the notch. With a quick

motion of the hands toward the body, the plastic is snapped in two.

Thin plastics, such as acetate and very thin laminate, can be cut with paper

cutters, tin snips, or large scissors specially designed for the purpose. Such

tools are available in plastics-supply stores.

Scoring and Snapping a Sheet of Acrylic

1 --- Preparing the acrylic for scoring. Mark the break line on the protective

paper covering the acrylic sheet, and lay a steel square along the line, clamping

both sheet and square to a work bench. Position the break line as far in from

the edge of the workbench as the jaws of the clamps will allow. Be sure the

positions of the clamps leave the break line free.

2 --- Scoring the acrylic. Using the steel square as a guide, score the acrylic

repeatedly along the break line with a utility knife or a scoring tool. Apply

firm, even pressure along the full length of the line, allowing each stroke

to run off the edge of the plastic, onto the workbench. The tool should produce

a thin, continuous curl on each pass. Make about 6 passes for sheets that are

up to 3/16” thick, about 10 passes for sheets up to 0.25” thick.

3 --- Breaking the sheet. Release the sheet and move it to the center of the

workbench, positioning the scored line, face up, over a ¾-inch dowel that is

at least as long as the line. Brace the wide part of the sheet with one hand

and press down on the narrow part, using the dowel as a fulcrum. The sheet

should snap cleanly in two.

If the sheet does not break in a single movement, place your bands at the

edge closest to you and apply pressure until a break begins. Then move your

hands along the line, keeping the heels of your hands about 2 inches ahead

of the point where the break ends, gradually elongating the break until the

sheet snaps in two. Cut the protective paper with a razor blade or a knife.

- - - - -

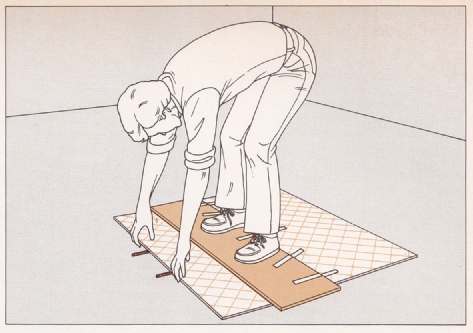

Using Body Leverage to Break a Large, Thin Sheet

---22

Snapping up against a straightedge. Mark the break line on both sides of the

sheet aligning them exactly, and score one side the necessary number of times,

as in Step 2. Race the sheet on the floor, scored side down, wedging two pencils

under the outer edge of the section to be snapped. Lay a board on the other

section, wide enough to stand on and at least as long as the width of the acrylic

sheet. Align the edge of the board with the break line, and secure the board

to the acrylic sheet with heavy tape. Then stand on the board and pull up on

the free section, snapping the sheet in two.

If the sheet is very wide, have a helper stand on the board while you stand

off the sheet and raise it up to break it. Cut through the protective paper

over the break with a razor knife.

Blade Types for Large Power Tools

Choosing the best blade for the job. The chart at right indicates the best

choice of saw blades to use with large power tools for cutting plastics of

varying kinds and thicknesses. Listed vertically in two general categories—band

saw and circular saw or table saw—are the materials to be cut, the type of

blade and the number of blade teeth per inch, In each case the blade listed

is the optimum choice, but substitutions are possible. For example, on the

band saw, all the listed types and thicknesses of plastics can be satisfactorily

cut with a skip-tooth wood-cutting blade. And although a carbide-tipped circular

- saw blade is ideal for those plastics with which it’s paired, a hollow-ground

blade for cutting plywood also does the job. The blades listed have odd names

but are commonly available. Skip-tooth blades are so called because of a tooth-wide

nap between teeth; regular blades for wood or metal have no gap between the

teeth. Hollow- ground blades are made with teeth wider than the blade plate,

and spring-set blades have teeth

Blade Types for Large Power Tools

===Choosing the best blade for the job.=== The chart at right indicates the

best choice of saw blades to use with large power tools for cutting plastics

of varying kinds and thicknesses. Listed vertically in two general categories—band

saw and circular saw or table saw—are the materials to be cut, the type of

blade and the number of blade teeth per inch. In each case the blade listed

is the optimum choice, but substitutions are possible. For example. on the

band saw, all the listed types and thicknesses of plastics can be satisfactorily

cut with a skip-tooth wood-cutting blade. And although a carbide-tipped circular

saw blade is ideal br those plastics with which it’s paired, a hollow-ground

blade for cutting plywood also does the job. The blades listed have odd names

but are commonly available. Skip blades are so called because of a tooth-wide

gap between teeth; regular blades for wood or metal have no gap between the

teeth. Hollow-ground blades are made with teeth wider than the blade plate,

and spring-set blades have teeth than point in alternating directions.

Material to be cut | Type of blade | Teeth per inch

Band saw

Circular saw or table saw

[

V acrylic

¼”- acrylic

1” and over acrylic

Laminates

Up to 3” cellulosics

Phenolics, melamine

Epoxies, polyester, acetal, polycarbonate

Polystyrene foam

Polyurethane foam (rigid)

Polyvinyl chloride (PVC)

9 “-¼” acrylic

¼”-%” acrylic

4” and over acrylic

Epoxies, melamine, phenolics, polyester

PVC, polystyrene foam, acetal, cellulosics, polycarbonate

Laminate

Polyurethane foam (rigid)

]

[

Regular metal-cutting

Regular metal-cutting or skip-tooth

Skip-tooth

Regular metal-cutting

Skip-tooth

Regular metal-cutting

Skip-tooth

Regular metal-cutting or skip-tooth Hollow-ground plywood-cutting

Hollow-ground plywood-cutting

Hollow-ground plywood-cutting or spring-set

Carbide-tipped

Hollow-ground plywood-cutting

Carbide-tipped

Hollow-ground plywood-cutting

]

Accurate Band-Saw Cutting with the Aid of Fences

----23a

1--- Setting up the saw. Install the proper blade (chart, opposite) and set

the saw for the correct speed; then set the blade guides 1/8 inch higher than

the acrylic sheet. Measure the distance from the cutting line, marked on the

sheet, to the waste edge of the sheet. Clamp a wood fence this distance from

the saw blade. The fence should extend to the near edge of the saw table and

1 to 2 inches beyond the blade. Check the distance from the fence to the edge

of the saw table at several points, to be sure the fence is parallel to the

table edge and consequently to the plane of the saw blade.

----23b

2---Making the cut. With the saw turned on, butt the acrylic sheet against

the fence and push the sheet forward against the blade. The blade should enter

the sheet just to the waste side of the cutting line. Feed the plastic steadily

past the blade, until the cut is complete. If one part of the stock is less

than 3 inches wide, use a push stick to help move the stock along.

Forming a Beveled Edge with Power Saws

===Using a table saw. Select the correct blade for the plastic and set it

at the desired angle, leaving the blade guard in place; for a smooth cut the

blade should be just higher than the thickness of the plastic. Place the plastic

on the saw :able, aligning the cutting line with the top of the blade. Butt

a wood fence against the plastic to hold it in alignment, and secure the fence

with clamps; the fence should extend from the near edge of the table to the

midpoint of the blade, but no farther.

Once the cutting position has been established, pull back the plastic and

turn on the saw. Then push the plastic past the blade, using the miter gauge

as a pusher.

===Beveling with a saber saw. Set the saw shoe at the desired angle, and clamp

the plastic to a worktable, sandwiching it between the table and a piece of

½-inch plywood. Position the plastic so that the cutting line overhangs the

table edge; place the plywood over it so that the distance from the plywood

edge to the cutting line equals the distance from the saw blade to the edge

of the shoe. Then turn on the saw and begin the cut, pressing the side of the

saw shoe firmly against the plywood.

Sawing Tubes and Rods

===Using a table saw with round stock. Hold the plastic tube, here PVC pipe,

against the face of the miter gauge. To position the stock, hold the plastic

against the saw blade, aligning the blade with the cutting line. To cut tubing,

turn on the saw, hold the tubing against the miter gauge and the stop, and

feed the tubing into the saw blade until the tubing is over the center of the

blade. Then begin to revolve the tubing, rolling it toward you, meanwhile holding

it securely against the miter gauge. Continue revolving the tubing until you

have cut completely around its circumference. File off any rough edges.

To cut a solid circular rod, raise the saw blade until it’s 1/16 to 1/8-inch

higher than the diameter of the rod. Brace the rod against the miter gauge,

and push the rod through the saw blade. For a rod greater than 3 inches in

diameter, mark the stock, push it past the blade, then turn it over and cut

the other side.

25a---

===Running a round stock through a band saw. Set the blade guides of the saw

so that they are 1/8 inch higher than the diameter of the tubing or rod. To

prevent the plastic from spinning when it passes through the saw blade, hold

it firmly against the miter gauge. Then slowly feed the plastic, here PVC pipe,

into the blade until it’s cut in two. For rods and tubing of small diameter,

you can use a block of wood cut with a V groove to hold the work steady (inset).

Curve-cutting Techniques

Contouring with a band saw. Prepare the saw by fitting it with the correct

blade, set ting it for the proper speed, and adjusting the blade guides to

sit 1/8 inch higher than the thickness of the plastic. Turn on the saw and

guide the plastic forward until the blade touches the waste side of the cutting

line. Then feed the piece steadily against the blade, pushing as fast as the

blade will cut easily and stopping only if the blade overheats and sticks.

For an intricate contour, begin with a rough cut, then gradually come closer

to the cutting line in several repeated cuts. Use the finishing techniques

shown to take the piece of plastic down to its final shape.

26a---

=== Shaping curves with a saber saw. Clamp the plastic to a worktable so that

part of the cutting line overhangs the table edge (left). Turn on the saw and

cut into the plastic from a waste edge coming into the cutting line at a shallow

angle. Follow the cutting line as far as you can until the table edge gets

in the way. Then turn off the saw, ease it out of the cut and re-clamp the

plastic so that another section of cutting line overhangs the table edge. Reinsert

the blade just behind where you left off, switch on the saw and continue to

cut. Repeat this procedure until the entire curve is complete.

To cut curves in thin plastic with a saber saw, sandwich the plastic between

two slightly larger pieces of ¼-inch plywood, nailing through the edges of

the plywood to fasten the sandwich together . Be careful that you are

not nailing into the plastic. Draw the cutting line on the plywood and clamp

the sandwich to the worktable, proceeding as above. Use a coarse blade for

this job, if you wish, since it has to be able to cut through the plywood.

Routing a V Groove for a Square Inside Corner

26b---

1 Setting up the cut. Draw a cutting line on the protective paper covering

the plastic, marking the center of the planned groove, and fit a V groove bit

into the router. Set the tip of the bit flush with the router base and measure

the distance from the bit tip to the edge of the base (above, left). Then set

a straight-edged guide on the plastic, placing the guide this distance from

the cutting line (above, right). Clamp the guide in place and recheck your

measurements.

27a---

2 Routing the groove. Set the depth of the router bit at one half the thickness

of the plastic, and place the router at one end of the cutting line so that

the bit just clears the edge of the plastic. Turn on the router and draw it

along the guide to make a V-shaped groove (inset).

A Professional’s Way to Cut Through Laminate

27b---

1 Preparing the cutting surface. Place the laminate, decorative side up, on

a worktable; mark the cutting line, then cover the line with a length of transparent

tape. Place the laminate so that the cutting line overhangs the edge of the

table by an inch or two. Clamp a piece of plywood over the laminate, positioning

the plywood so that its edge can be used as a cutting guide; the plywood will

also help to control the vibration of the laminate as a circular saw cuts through

it.

28a---

2. Sawing the laminate: Fit the circular saw with a plywood-cutting blade

that has 6 to 10 teeth per inch and set the blade depth to 2 inches. Place

the table at one end of the cutting line; then on the saw and push it forward,

using the edge of the plywood as a guide.

To cut a large a piece of laminate in two, set up the work as in Step 1, with

the cutting line over a the edge of : table by an inch or two; but with a larger

piece you must rest the unsupported end of the laminate on sawhorses or a :a

e about the same height as the worktable.

Making an Interior Cut in a Sheet of Laminate

===Setting up the work. After marking the cut ting line, clamp the laminate,

decorative side up, to a piece of scrap plywood, hardboard or particle ,board

and place the work on a pair of 2-by-4s laid across sawhorses. Drill a pilot

hole for the saw blade an inch or two inside the cutting line. Insert the saw

blade in the hole and cut around the outline.

If the laminate is already glued to a plywood base, as for a sink in a countertop,

eliminate the 2- by-4s and the plywood or particle board, and rest the work

directly on the sawhorses.

When cutting a glass-reinforced plastic or material that is stiff enough not

to need backing but is also brittle—a synthetic marble, for in stance—never

attempt to cut square corners; they create stress points that may cause the

laminate to crack. To round corners with a tight radius, drill a hole at least

1 inch wide at each corner with a hole saw or a drill, then connect the holes

to complete the outlines.

|