Introduction to Knitting Machines

After discovering the joys of the sewing machine and serger, the sewing public is eager for other exciting outlets for their creativity. The newest entry into the home-arts machine market is the knitting machine.

People are using the knitting ma chine in exciting combinations with their other machines: knitting a matching ribbing for a knit fabric, for example, or knitting flat yardage which is cut and serged into whole sweaters or parts of garments. Others use their knitting machines for the boring parts of hand- knit sweaters, such as the backs and sleeves.

After spending time investigating this newest craze, I have decided it's almost impossible for a consumer to determine which model or type is best without having some basic background information.

The alternatives in knitting machines and knitting frames are so varied that it’s easy to become over whelmed and confused. Each type of knitting machine has strict limitations on the features it can offer and the thread weight it can handle.

The information in this section will be presented in a different way than for the sewing machine and serger sections. The focus will be on how each type of knitting machine functions and how each differs from the others.

This section doesn't pretend to offer the whole story on knitting machines, but it does give you the essentials and a way of understanding the differences so that you can make in formed choices.

How a Knitting Machine Really Works

I am not as expert on knitting machines as I am on sewing machines and sergers, but I have used my mechanical expertise to present an unbiased point of view, describing how they work from a functioning viewpoint—beyond the flurry of information and claims.

All knitting machines make a knitted stitch, not a crochet stitch or macramé knot. The knitted stitch is an interlocking row of loops that build on each other. The knitting-machine stitches are exactly like hand-knit stitches, except they are more even.

A knitting machine does the actual knitting of the yarn. You don’t need to know how to knit to operate the ma chine. You do need to know how to operate the knitting machine, however, whether or not you know how to knit. In this respect, the novice or expert start at the same level.

A hand-knitter will have the ad vantage after learning to operate a knitting machine. Techniques such as shaping will be easier to grasp if you know how to knit by hand, and your creative ideas may develop faster with a hand-knitting background.

Types of Knitting Machines

All knitting machines and knitting frames make stitches with a series of latch hooks, instead of with two standard knitting needles. These hooks are commonly referred to as needles, but I will continue to call them hooks be cause that's how they look and function.

There is one hook for each stitch in a row. Hooks hold the looped stitches in place. To make a new row, the carriage is pulled across the bed. The hook grabs the new yarn and pulls it through the old loop to make a new stitch.

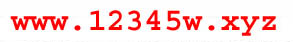

The main difference between the two types of knitting machines is the size of the needles (hooks) and the space between them. The two basic categories, with tiny variations from brand to brand, are standard and bulky.

The standard size is the smaller of the two varieties and uses fine yarns. The maximum thickness is the width of fingering yarn. A heavier sweater can be made by using more than one yarn at a time. The standard-size knitting machine gives a smoother, tighter look to the finished product, with a distinctly machine-knit quality.

Fig 11-1 Hook sizes: standard, bulky

The simplest style of knitting ma chine is usually referred to as a knitting frame instead of a “machine.” The main difference is the method of adjusting the thread tension.

The bulky knitting machine uses thicker knitting yarns. The hooks are much larger and farther apart. The finished product will closely resemble a hand-knit garment.

Small yarn on a bulky machine will yield a narrow, knitted piece. The large needles remain the same distance apart, and the number of stitches per row is limited to the number of hooks. The finished product will be very loose and flimsy.

A Knitting Machine’s Basic Paris

The basic parts of a knitting ma chine are:

1. Hooks—These small latch hooks function as the knitting needle and are often referred to as needles. For the sake of clarity, I will continue to call them hooks. The hooks come in two basic sizes—standard and bulky (Fig. 11.1).

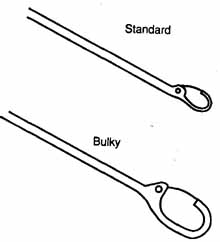

2. Bed—The bed is a long flat surface with grooves to hold the hooks (Fig. 11.2).

Fig 11-2 Single-bed knifing machine

3. Carriage—The carriage slides across the bed and carries the yarn through the hooks to form new stitches.

4. Tension—The tension dial or key plates regulate the amount of pull on the thread.

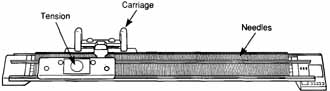

5. Transfer tools—These prongs with handles can have a latch hook at the end or one or more rounded end(s), each with an eye (Fig. 11.3).

Fig 11-3 Transfer tools

6. Weights—The weights hang from the knitting and hold the loops in the hooks. There are both weights that hang from the whole knitted piece and small ones that hang from an exact area that needs additional hold.

7. Wax—The carriage needs wax to slide smoothly over needles.

8. Knitting machine table—Knitting machines are wide and require careful anchoring. They work best anchored to a surface made specifically for the machine.

Knitting machines have many options and accessories. Some come with the machine and some must be added on. Be aware that the options are usually not interchangeable. Only certain models and brands can accept additional parts. Check the manual care fully before you make a decision.

How to Choose the Right Machine

The question of options and choices can be complicated. To help you decide the best type of machine for you, use the worksheet in Fig. 11.4.

Fig. 11.4 Checklist for Purchasing a Knitting Machine:

• What type of finished product do you prefer? Hand-knit appearance Fine, soft look of ready-to- wear • What categories of yarn will you use most (weight and variety)? Very fine, almost thread weight Mohair or other fuzzy types Bulky wools, including handspun Varying thickness, slubs, and /or loops • What design options do you want? Variety of patterns Lacework Color changes — both Fair Isle and intarsia Ribbing—by hand or by machine • What kind of automation do you want? Punch-card Electronic Shaping • Do you want weights? • What size machine would be best? Standard (pluses and minuses) Bulky (pluses and minuses) Interchangeable • How much knitting do you plan to do? How much time are you willing to devote to learning machine operation? Will the machine be cost effective? Will you use the machine only as a hobby? • Where should you purchase the machine? * What are the dealers lesson policies?

Is instructor expertise available? Is the dealer reliable? What is the repair procedure? * This would be my number-one consideration, once I made the decision to buy. |