The slab-on-grade foundation is another type not widely used in log construction, but it easily could be because it's quite effective and popular with other types of houses. Its disadvantages for the do-it-yourselfer are that it re quires a source of ready-mix concrete; a considerable amount of site preparation that often includes laying a sand or gravel cushion on which to pour the concrete; and a crew of workers to form, emplace, and finish the slab.

This is a big job that must be compressed into a relatively short period of time, and done just right. In addition, certain elements of the electrical, plumbing, waste disposal, and some times heating systems must be carefully planned out and installed in exactly the right places before the concrete is poured. Once the slab is in place, any mistakes can't be rectified without a great amount of difficulty.

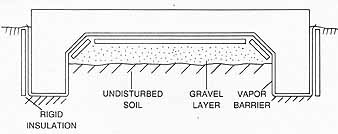

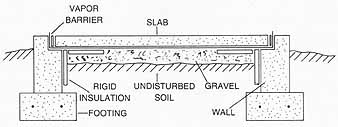

Slab-on-grade foundations can be made in one monolithic pour, or in three steps. The first system is accomplished by pouring the footings, short stem walls, and floor slab all in one operation (Fig. 4-27). The second system consists of making footings first, then the, stem walls, and finally pouring the slab (Fig. 4-28).

Fig. 4-27. A monolithic or one-pour slab-on-grade foundation.

Fig. 4-28. A slab-on-grade foundation made in three parts: footing,

stem walls, and floor slab.

Preparation involves digging the footing trenches and smoothing out the slab area, and adding a layer of compacted sand or gravel if necessary. The footing trenches and the gravel cushion are covered with a layer of overlapped heavy plastic film to form a vapor barrier. Rigid thermal insulation is often placed beneath the vapor barrier. Side forms are erected around the perimeter of the foundation to contain the wet concrete. Reinforcing mesh is laid out in the floor area, and reinforcing rods set throughout the footings. Meanwhile, all pipes, electrical conduits, heating ducts and other necessary items are set in place. When all this is completed, the pour is made, leveled and screeded, and then finished and cured. Anchor bolts are set in the fresh concrete as necessary. After curing, the side forms are removed. Rigid thermal insulation may be placed along the footing perimeter, and then the remaining excavation is backfilled.

Among the advantages of this type of foundation is that it can be built in a relatively short period of time without an excessive amount of site disruption (usually). It also provides great flotation and stability for the structure by reducing ground loading to a low point—and thus is useful on unstable or soft soils, and it provides an extremely solid first floor. How ever, it must be fitted with a vapor barrier, and with insulation in cold country, and be properly engineered and built to avoid the common problems of cracking, buckling, or distortion.