|

TOOLS AND MATERIALS:

Stripping wallpaper: Drop cloths, steam stripper, warm water, garbage

bags

Washing down and filling: TSP, hot water, sponge, oil- based undercoat

(optional), brush, spackle, 2-in (50-mm) knife, sandpaper

Filling cracks: Caulk, caulk gun, sponge, brush, oil-based undercoat*

STRIPPING WALLPAPER

Steam strippers work most efficiently when top layers of paper have

been removed, exposing the more absorbent backing paper. The impermeable

surface layer of vinyl papers often peels dry, relatively easily. Always

follow the manufacturer’s guidelines. Wear protective gloves, if the

tool’s manual recommends them, and goggles. Steam and drips may burn,

so take all possible precautions to protect yourself. Never use a steam

stripper to remove paper from a ceiling. Instead, simply soak the paper

with warm water and then scrape the paper off the ceiling surface,

an option that can also be used on a wall if you prefer.

A. Lay drop cloths over the room, and remove as much loose paper from

the wall by hand as you can.

B. Fill the stripper with warm water before plugging it in. When it

starts to steam, place it flush on the wall.

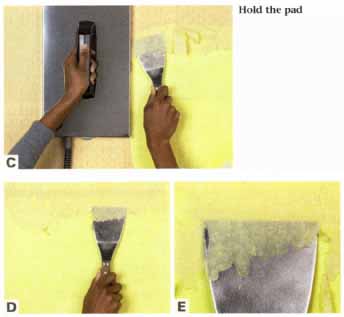

C. Hold the pad completely flush on the wall surface. After 5 - 30

seconds, move it along and scrape paper off the wall in the steamed

area. The thicker the layer(s) of paper, the longer you will need to

hold the pad in place. But do not hold it still for too long or the

wall surface itself may crumble.

D. Work your way across the wall, steaming areas and removing paper.

E. Continue removing paper. Put it in a garbage bag as you remove

it, so that it does not stick to the drop cloth or other surfaces.

WASHING DOWN A WALL AND FILLING HOLES

After a wall has been stripped, wash the surface thoroughly to remove

all traces of adhesive. Use soapy hot water to sponge the wall. Then

rinse with clean water. You can now repaper the wall. If you wish to

paint the wall, apply an oil-based undercoat before a water-based latex

paint. However well the wall has been cleaned, traces of adhesive may

bleed through a water- based paint; oil-based undercoat prevents this.

It is needed on a previously painted wall only if the wall is in poor

condition.

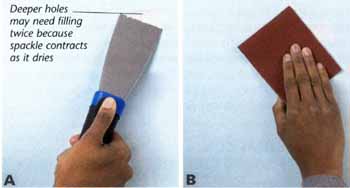

A. Clean out the hole with a dry brush. Apply filler by pressing it

in place with a 2-in (50-mm) knife. Deeper holes may need filling twice

because spackle contracts as it dries.

B. Once the spackle has dried, sand it back to create a smooth surface

flush with the surrounding area.

FILLING CRACKS

Cracks are best filled using caulk. It is supplied in a tube and is

applied along cracks or joints with a caulk gun. It can't be sanded, and must therefore be smoothed by hand before it dries. Some caulks

may be over-painted when dry. Choose a latex caulk if you think you

may paint. Others need an oil-based undercoat to prepare them for water-based

paints, which may crack if there is no undercoat. A ceiling-wall junction

is shown here.

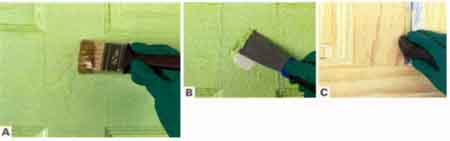

A. Clean out the joint. Prepare the sealant and gun. Apply even pressure

to the trigger, moving the gun along the joint.

B. Gently smooth the sealant with a wet finger. You may also use a

damp sponge to smooth the caulk.

NEW WALL AND CEILING SURFACES

Plaster in a good condition can be directly over-painted with full-strength

paint, Alternatively, first apply a mist coat of diluted latex paint

(1 part water to 10 parts paint), which provides a base for further

coats. Drywall ceilings must be coated with a special sealer before

paint is applied, otherwise paint may dry differently on the board

than on the jointing compound.

WORKING WITH WOOD

Woodwork provides the finer detailing in a home and its finish is

a stamp of quality. To produce good results you must prepare surfaces,

including doors, windows, and decorative woodwork for moldings or paneling.

TOOLS AND MATERIALS:

Using a heat gun: Shave hook

Solution stripping: Old paintbrush, scraper or shave

hook, cloth, mineral spirit or water

Paste stripping: Filling knife or small trowel, stripper,

covering cloth, cleaning cloth, neutralizing solution/white vinegar,

water

Covering old paint: Oil-based eggshell paint, paintbrush,

brush-cleaning solution, mid-oak wood stain, varnish, oil, or shellac,

two cloths

Priming and filling before painting: Knotting solution,

paintbrush, filling knife, sanding block, filler, primer

Filling for a natural wood finish: Filling knife,

filler, sanding block

Stripping wood

A good finish is often achievable by recoating the existing surface.

However, you may need to strip woodwork before redecorating—the existing

coating may be so bad that it can't be successfully recoated; it may

be painted, but you want a natural wood finish; or it could have a

natural finish but you want to paint it or apply a different finish.

Beware of surfaces with lead-based paint, which is toxic and now found

only in older properties. It is a health risk if heated with a heat

gun, and fine particles created by sanding are also toxic. Paint-testing

kits are available to identify lead-based paintwork.

USING A HEAT GUN

A. Turn the heat gun on and direct the nozzle at the wood surface,

leaving a gap of a few inches between the two.

B. After a few moments, the paint will begin to soften and bubble,

which point use a shave hook or scraper to lift the old paint free.

C. Move the gun along to the next area and repeat the process. Use

a shave hook to remove paintwork in recesses, such as on paneling.

WORKING SAFELY

- Take great care using a heat gun. Wear goggles and a respiratory

mask, and perhaps gloves. Take any other precautions that are advised

by the tool’s manufacturer.

- Do not hold the gun for too long over the wood, to avoid the risk

of scorching it or even setting it on fire.

SOLUTION STRIPPING

A. Wearing gloves, a mask, and goggles, use an old paintbrush to apply

the stripper. Use dabbing strokes to build up a good layer of the stripper

on the wood’s surface. Allow it to soak in and react with the paint.

This may take only a couple of minutes or up to half an hour.

B. Once the paint has bubbled up, scrape it off using a scraper and /or

a shave hook.

C. Thoroughly clean the surface afterwards. Mineral spirit and cold

water are usually best, but check the stripper manufacturer’s guidelines.

PASTE STRIPPING

A. Apply the stripper with a filling knife or small trowel to a depth

of about in (2.5 mm) -- or deeper if there are many coats of paint.

B. If your manufacturer specifies it, cover the entire surface with

a special cloth. Leave for 24 hours. Use a scraper to peel away the

paste.

C. Thoroughly clean down the area. If the manufacturer suggests it,

use a “neutralizing solution”; or use white vinegar and then clean

water.

DIPPING DOORS

Removable items such as doors can be “dipped” professionally. The

whole item is submerged in a tank of powerful chemicals, which lift

all traces of paint from the wood surface. Many companies offer a pickup and delivery service.

COVERING OLD PAINT

Sometimes a natural wood finish may not be possible—if the wood is

too rough, or the paint too ingrained to strip. Old beams may have

stained finishes or may have been painted at some stage. You can have

the paint sand- blasted away by a professional company but this is

expensive, and extremely messy. An alternative is to apply the paint

effect shown here.

A. Completely paint the beam, using an oil-based white eggshell.

B. Apply a wood stain over the top of the eggshell. A mid-oak color

is very effective.

C. Rub varnish, oil, or shellac across the whole surface to provide

the effect of an oak beam.

D. After half an hour, buff off the varnish, oil, or shellac with

a clean cloth. Some will remain embedded within the wood grain, resulting

in the appearance of a natural wood beam.

PREPARING BEAMS

Natural wood beams are often tricky items to prepare for decoration,

because of flaky surfaces and often very crumbly edges where the beam

meets plaster. Trying to fill the edge is difficult and often ineffective,

as the filler too crumbles and falls away.

One way to secure the edge is to apply a clear matt varnish to the

beam, overlapping slightly onto wall or ceiling surfaces. The varnish

both binds the surface and provides a natural look. The wall or ceiling

paint may then be cut in along the edge to create a neat finish.

FILLING AND SANDING WOOD

Wooden surfaces are seldom completely smooth. Filling dents and sanding

improves the finish. The type of filler to be used depends on whether

the wood is to be painted or a natural finish applied. If it's to

be painted, use powder filler—flexible filler can be used in joints

or cracks. If a natural wood finish is to be applied, use a “stainable”

filler the same color as the finish. See this page for choosing a suitable

primer.

PRIMING AND FILLING BEFORE PAINTING

A. Prime bare wood before using filler, to make it

adhere better. Primer also makes it easier to see areas that require

filling. If wood is painted, use primer only if there are large, bare

patches—for instance, on external woodwork. Any knots in bare wood

must first be coated with knotting solution.

B. Allow primer to dry. Mix up filler, and apply to holes, dents,

or divots, using the flexibility of a filling knife blade to press

in the filler.

C. Allow filler to dry. Sand to a smooth finish. Deep holes may require

refilling and sanding to provide the best finish.

FILLING FOR A NATURAL WOOD FINISH

A. Apply colored putty to holes in the wood surface with a putty knife.

The putty color should match the natural wood finish to be applied.

B. Once the putty has dried, sand it smooth. Then apply coats of your

chosen finish.

FURTHER INFORMATION

Sanding

Sandpaper should be chosen according to the condition of the surface.

So, for rough surfaces, begin by using a rough paper. As the surface

becomes smoother, reduce the coarseness of the paper.

Remember that sanding produces dust. This should always be brushed

away before a coating is applied. A vacuum cleaner nozzle is ideal

for removing dust from baseboards or the profiles of moldings.

The best finishes are normally achieved when the wood has been wiped

down with a damp cloth before coating, removing the finest residues.

This is essential when sanding flat surfaces such as window sills.

|